Electrocatalysis

1. Electrocatalytic CO2 Reduction

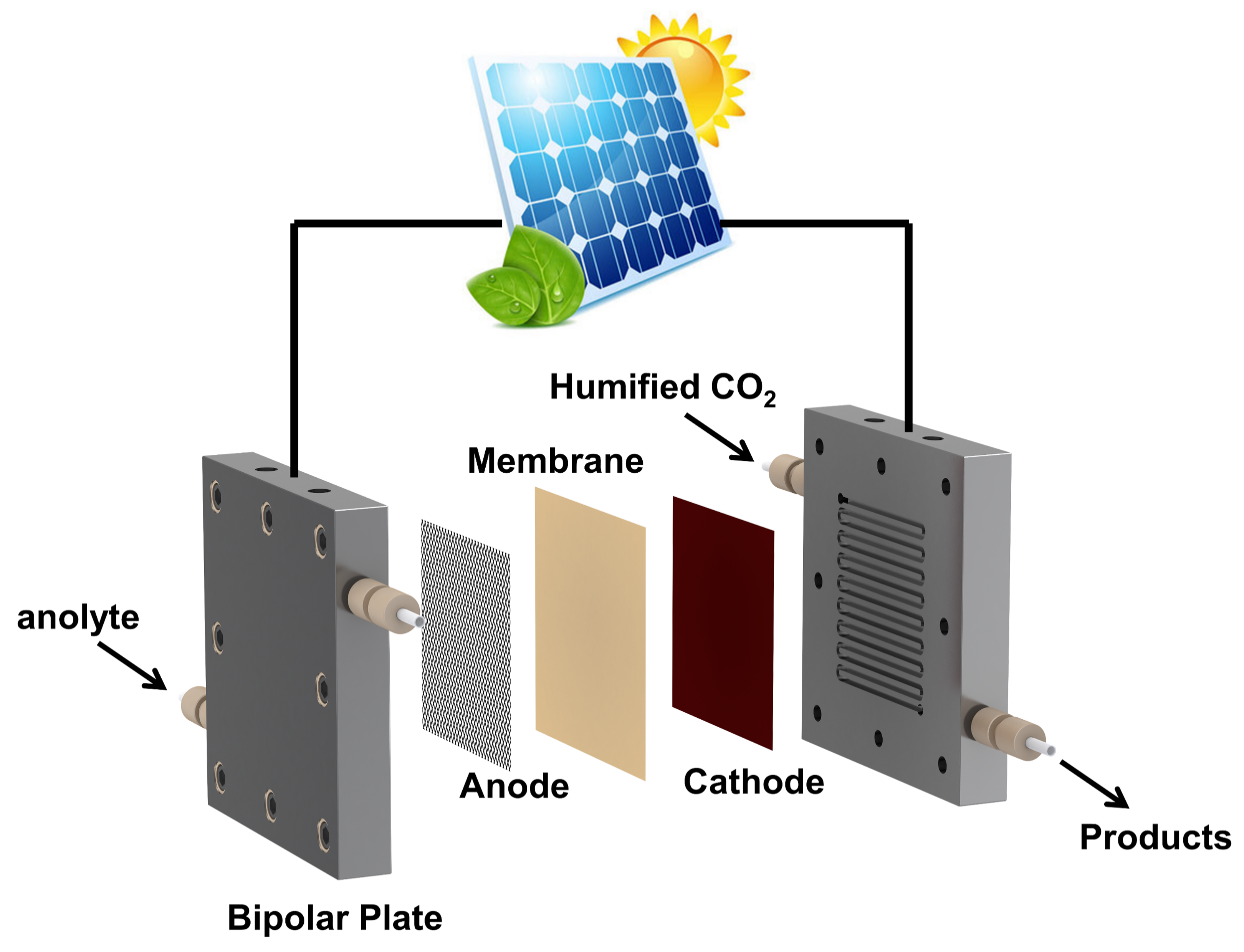

●Investigation of electrocatalysts and manipulation of multi-physics fields within CO2 reduction devices

●Design of novel reactors to break mass transfer limitations for the industrialization of CO2 reduction systems

2. Electrochemical Production of Green Hydrogen

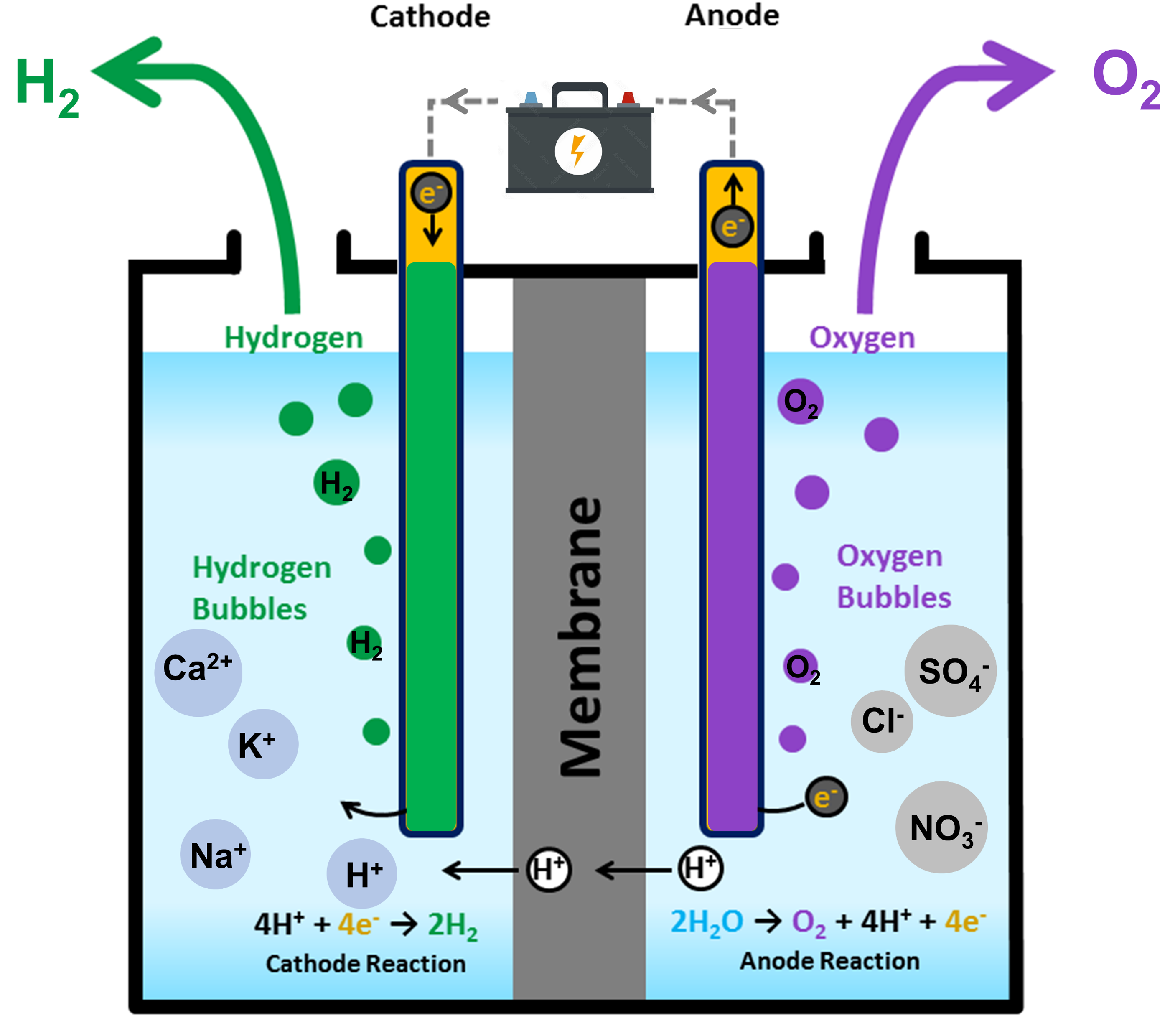

Green hydrogen is the key to build up a carbon-neutral society. Electrochemical water splitting by renewable electricity is a promising way to obtain green hydrogen. We focus on the synthesis of inexpensive transition metal-based electrocatalysts to replace precious metal electrocatalysts for water splitting. Meanwhile, we study the direct electrolysis of seawater and design stable and corrosion-resistant catalysts to produce hydrogen. In order to improve the current density and stability of water splitting systems, our team also investigate the behavior of bubbles in the electrolyte. By regulating the fluid flow pattern, we seek to reduce the ohmic resistance drop, improve the energy conversion efficiency, and eventually achieve the long-term operation of the hydrogen production devices.

Green hydrogen is the key to build up a carbon-neutral society. Electrochemical water splitting by renewable electricity is a promising way to obtain green hydrogen. We focus on the synthesis of inexpensive transition metal-based electrocatalysts to replace precious metal electrocatalysts for water splitting. Meanwhile, we study the direct electrolysis of seawater and design stable and corrosion-resistant catalysts to produce hydrogen. In order to improve the current density and stability of water splitting systems, our team also investigate the behavior of bubbles in the electrolyte. By regulating the fluid flow pattern, we seek to reduce the ohmic resistance drop, improve the energy conversion efficiency, and eventually achieve the long-term operation of the hydrogen production devices. ●Corrosion-resistant catalysts for the electrolysis of seawater

●Modulation of the growth and desorption behaviors of bubbles

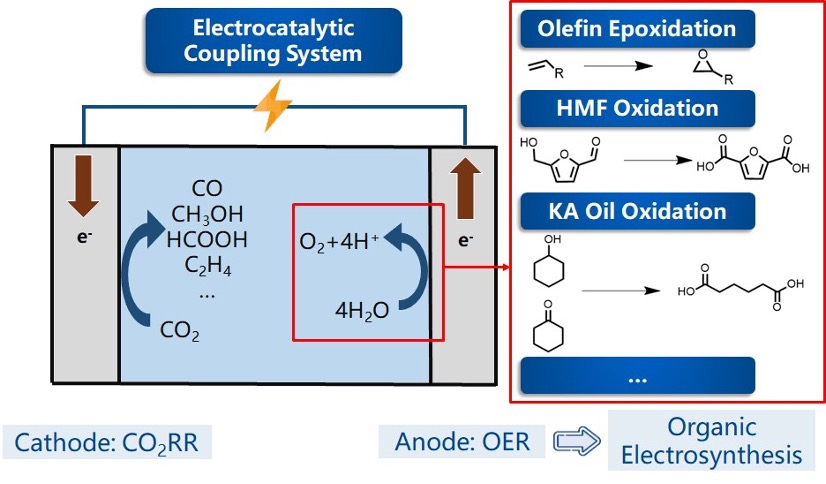

3. Electrochemical Organic Synthesis

The pursuit of a carbon-neutral society requires innovative approaches, among which sustainable electrochemical synthesis stands as a key pathway for the efficient production of high-value chemicals and fuels. We are dedicated to developing highly selective electrochemical systems that replace energy-intensive thermal or chemical processes, focusing on the rational design of catalysts and the optimization of reaction engineering. We also focus on constructing energy-efficient coupled systems that pair cathodic reactions (e.g., CO2RR) with anodic organic oxidation to replace the conventionaloxygen evolution reaction (OER), thereby simultaneously producing high-value products and significantly reducing energy consumption.

Current projects include:

●Catalyst and System Design for Electrocatalytic Conversion of Biomass and Feedstocks

●Electrochemical Reaction Engineering and Reactor Design for industrial scale-up

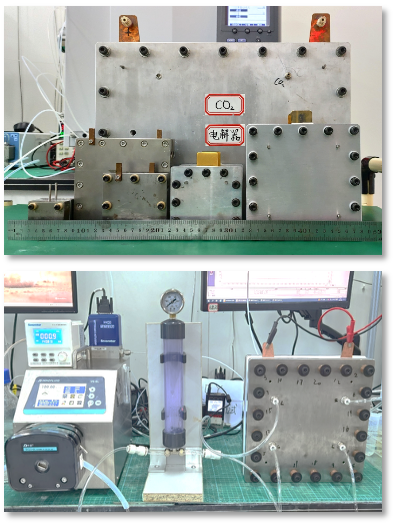

4. Engineering Electrochemical Stacks for Industrial Scale-Up

The industrial scale-up of electrochemical CO2RR is critical to realizing a sustainable carbon cycle and a carbon-neutral society. We are dedicated to bridging the gap between laboratory research and practical application, focusing on the engineering of advanced reactors and the optimization of system integration. By assessing the long-term stability and efficiency of CO2RR under industrial-relevant conditions, we aim to verify the feasibility of the process and accelerate the practical deployment of green chemical manufacturing.

Current projects include:

●Design and optimization of reactors and electrolyzers for electrochemical CO2 reduction

●Development of robust pilot testing systems for process intensification and performance validation to assess the long-term stability and feasibility of the CO2 electrolysis process